In recent times, ceramic coating has become a very popular choice for protecting vehicle exteriors. Although it is well-known among car enthusiasts, ceramic coating is also widely used in marine, aerospace, construction, and manufacturing industries. These coatings offer robust protection against harsh environmental conditions, making them ideal for applications beyond just automotive use.

Now a question arises “How long does a ceramic coating last?” Well the answer to this isn’t very straightforward as many factors come into play. With the right product and proper care, the ceramic coating can last for years. It’s going to retain that showroom shine and give maximum protection to your vehicle.

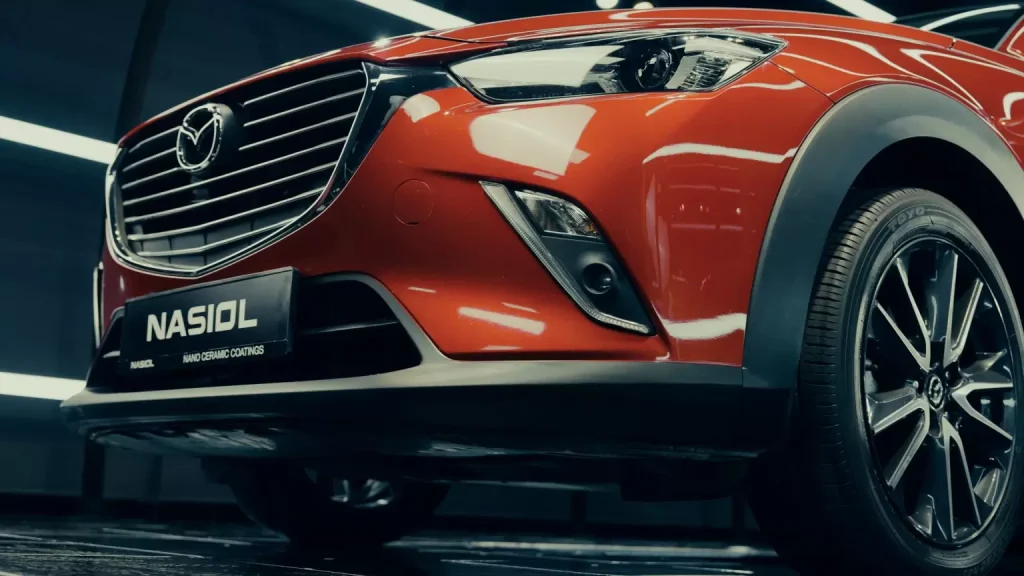

Due to the leadership of Nasiol in nanotechnology-based protective solutions, it offers some of the most long-lasting ceramic coatings in the market today.

What is Ceramic Coating?

Ceramic coating is a liquid polymer that is applied to a car’s exterior. When applied appropriately, it forms a chemical link with the vehicle’s factory paint, creating a very durable and long-lasting protective coating.

If you want to learn more about the components of ceramic coatings, feel free to visit our blog for detailed insights and expert advice.

Traditional waxes or sealants lay on top of the paint, however ceramic coatings adhere to the surface semi-permanently or permanently, making them very resistant to environmental variables including UV radiation, dirt, water, and chemicals.

Nasiol have engineered high-quality nanotechnology products like Nasiol ZR53 and Nasiol NL272, which are designed to provide maximum protection to your vehicle exterior along with enhancing the vehicle appearance with a deep, glossy finish.

Factors Affecting the Longevity of Ceramic Coating?

There are many several factors on which the longevity of ceramic coating heavily depends. Understanding these factors will help you to maximize its benefits and prolong its durability.

1. Quality of the Product

The quality of ceramic coating products is crucial due to the chemical properties that determine their durability and effectiveness. High-quality ceramic coatings typically contain a high concentration of silicon dioxide (SiO₂) or titanium dioxide (TiO₂). These substances form a covalent bond with the surface, creating a strong, durable, and chemically resistant layer. This bond forms a stable network structure that can withstand environmental stressors like UV radiation, high temperatures, and chemical exposure, thus extending the lifespan of the coating.

In contrast, low-quality ceramic coatings often use lower concentrations of these active ingredients or substitute them with less effective compounds. Chemically, this results in a less dense network structure with weaker bonding to the surface. As a result, the coating is more vulnerable to degradation from environmental factors. For instance, exposure to UV light can break down weaker coatings more quickly, causing them to lose their protective properties and hydrophobic effect. Similarly, lower-quality coatings may not resist chemicals or abrasives as effectively, leading to premature wear and breakdown.

This chemical instability means that low-quality coatings deteriorate faster and lose their protective capabilities sooner, necessitating more frequent reapplications. In essence, while low-quality products might be less expensive initially, their chemical inefficacy and reduced durability lead to higher overall maintenance costs and less reliable protection for the surface.

2. Application Process

The procedure of how ceramic coating is applied has a great impact on the durability. Typically it is suggested that coating should be done by a professional as they do it more diligently. However, Nasiol products are designed for both end users and professionals, so if you are a DIY enthusiast you don’t need to worry.

But it is still very crucial to know the correct application process regardless of whether you’re doing it professionally or all by yourself.

To ensure optimal results and avoid potential mistakes, make sure to read the instructions carefully and watch application videos before applying a ceramic coating.

3. Environmental Aspects

Durability is heavily influenced by the environment in which the vehicle is used and stored. For example, vehicles exposed daily to severe weather conditions such as intense sunlight, heavy snow, or acid rain can experience a shorter coating lifespan. These harsh environmental factors can accelerate the breakdown of the ceramic coating, leading to diminished protective capabilities over time. Similarly, frequent exposure to industrial fallout—such as pollutants and airborne contaminants—and salt from coastal areas can exacerbate wear and corrosion, further reducing the coating’s effectiveness and longevity.

However, Nasiol’s ceramic coatings are specifically engineered to combat these challenges. They are formulated with advanced technology and high-quality materials that enhance their resilience against extreme environmental conditions. Whether it’s resisting the damaging effects of UV rays, withstanding the corrosive impact of salt, or enduring the harshness of industrial pollutants, Nasiol’s coatings are designed to provide robust and long-lasting protection. This ensures that even in the most challenging environments, Nasiol’s ceramic coatings maintain their protective properties and keep your vehicle looking and performing its best.

4. Maintenance and Care

Proper maintenance will help to extend the life expectancy of a ceramic coating. Continuing to wash it regularly with pH-neutral soaps and avoiding abrasive cleaning tools are factors for keeping the integrity of such a coating.

Nasiol offers a line of maintenance products, including Nasiol Cleanion Pro , professional-grade car shampoo that effectively removes dirt, grime, and contaminants from surfaces without damaging the underlying nano-coating.

It helps in prolonging the life of the coating by preserving its hydrophobic and oleophobic properties, which are key to repelling water, oils, and other substances.

Typical Lifespan of Ceramic Coating

We discussed the factors on which the durability of ceramic coating depends but users usually ask the lifespan of ceramic coating.

Nano ceramic quality usually lasts longer than the typical wax, this is one of the reasons why we are witnessing decline in demand for wax and rise in nanotechnology products.

On average, a high-quality ceramic coating can last up to 2 to 5 years and also depends on the factors mentioned above. However, some of our Nasiol products can exceed the timespan to 7 years.

Nasiol NL272, for instance, is popular due to its extreme durability of up to 5+ years which can be exceeded if maintained properly. These kind of product who offers such a great durability are not usually found in the market

Using advanced nanotechnology, Nasiol’s coatings develop a stronger bond with a vehicle’s surface, ensuring a more durable protective layer. Cases and testimonials abound on the increased lifespan of Nasiol’s coatings; hence, they are top-rated among people who love their cars worldwide.

How to Maximize the Longevity of Your Ceramic Coating

The next few steps will help you get the most out of that ceramic coating. First of all, proper maintenance is called for by washing your vehicle regularly using a car shampoo that won’t break down the coating with contaminants because it has a balanced pH.

Specialized products enhance and maintain the protective layer even better. Nasiol MetalCoatF2 can help you to maintain the protective layer over time and its advanced formula, it has high chemical resistance and durability against scratches.On top of that, all necessary application accessories are provided in the product box so you don’t have to purchase anything else.

Also, try to keep your vehicle away from harsh conditions to a great degree by parking it in a garage or under a shade, which will help eliminate radiant UV rays and weather extremities.

Finally, have your coating checked regularly by a professional to ensure that it is still present and to solve minor problems before they become major ones. By following these tips, you can help extend the life of your ceramic coating and ensure your vehicle remains protected and looking its best at all times.

Final Thoughts on Ceramic Coating Longevity

We can all agree that ceramic coating is a worthwhile investment and to not regret your investment at all it is very important not to compromise with the product’s quality.

Nasiol Ceramic Coatings with their wide range of products offer gold standard durability which is not often seen in the market, and some practices for regular maintenance can ensure your coating lasts for years.

Don’t compromise on the quality—choose Nasiol for the best in ceramic coating protection.

FAQ’s

1.How long does a ceramic coating last?

The normal period of use for high-quality ceramic coating ranges from 2 to 5 years and could be up to 7 years if properly cared for.

2.What are the factors that affect the lifespan of a ceramic coating?

The lifespan of a ceramic coating is influenced by several factors, including the quality of the coating itself, the environmental conditions it is exposed to, and the level of maintenance it receives.

High-quality coatings, like those from Nasiol, are designed to last longer, but harsh environmental elements such as extreme temperatures, UV exposure, acid rain, and industrial fallout can gradually degrade the coating over time. Proper maintenance, including regular washing with pH-neutral shampoos, avoiding harsh chemicals, and applying booster products, plays a critical role in preserving the coating’s protective properties and extending its lifespan. Additionally, how the vehicle or surface is used and stored—such as frequent exposure to outdoor elements versus being kept in a garage—can also significantly impact the longevity of the ceramic coating.

3.Can I perform ceramic coating by myself?

Nasiol’s products are also user-friendly for the DIY enthusiast, but it is best applied professionally.

4.How do I maintain my ceramic coating?

Hand washing your vehicle with a soft microfiber mitt is recommended over automatic car washes, which can be too abrasive. For deeper cleaning, a clay bar treatment can be performed occasionally, paired with a product like Nasiol Cleanion Pro to ensure the surface is spotless without harming the coating. Also, Periodic reapplication of a top-up ceramic coating, such as Nasiol ZR53 or Nasiol NL272, every 6 to 12 months can maintain optimal protection.

5.Why Nasiol Ceramic Coatings?

Nasiol is committed to producing REACH-compliant products, meaning that their ceramic coatings and other surface protection solutions meet the stringent safety and environmental standards set by the EU. This compliance not only ensures the safety of the users but also contributes to environmental protection.

Nasiol’s blend of advanced technology, global reach, and commitment to safety and sustainability makes them a trusted choice in the surface protection industry. Whether you’re looking for long-lasting ceramic coatings or environmentally conscious products, Nasiol has a solution to meet your needs.