Nano coatings are thin layers of surface coatings that can be made from different materials that are precisely engineered at the molecular or atomic level, typically involving materials with structures measured in nanometers (one nanometer is one billionth of a meter). The main aim of nanocoating is to protect the outer layer or to enhance the surface properties of different materials. It covers the surface of the objects and offers multiple benefits to maintain and preserve the actual beauty and property of products.

Common materials to form nanocoatings include nanometer-sized particles such as silica (SiO₂), titanium dioxide (TiO₂), zinc oxide (ZnO), and carbon-based materials like graphene or polymer mixtures, including modified nanoparticles like siloxanes.

Nanocoatings often involve strong chemical bonds, such as covalent bonds, which can form between the coating and the substrate surface. This ensures the coating’s durability and longevity. The distinction between nanocoatings and other types of surface treatments, like waxes, oils, or sealants, largely comes down to the nature of the bonding and the structural integrity of the applied layer, making them stronger, more durable, and longer lasting.

Nanocoatings are widely used in industries to extend the lifespan of products by preventing environmental damage, scratches, corrosion, color fading, and stains. This enhances the product’s durability and economic value.

Ever wonder how a thin layer of nano coating can significantly reduce an ecological footprint? This blog will delve into the fascinating world of nanocoatings and their potential to positively impact the environment.

What are the Main Advantages of Nasiol Nanocoatings?

Precisely engineered coatings using advanced nanomaterials—such as aerogels, silica and titanium dioxide nanoparticles, and graphene—create an ultra-thin, highly durable layer that forms strong molecular bonds with the substrate. This nanoscale architecture provides a uniform, continuous coating that is nearly invisible yet highly effective, offering robust protection to the material’s surface. These coatings significantly extend the lifespan and maintain the integrity of materials, even in harsh environmental conditions.

Let’s explore the other well-known benefits and unique properties of Nasiol Nano Coatings.

- Anti-corrosion

- Hydrophobicity

- Oleophobicity

- Scratch resistance

- Easy to clean

- Anti-graffiti

- Anti-mold

- Stain resistance

- UV protection

- Chemical protection

- Anti-microbial and anti-viral

- Renovation

How Can Nano Coatings Reduce the Ecological Footprint?

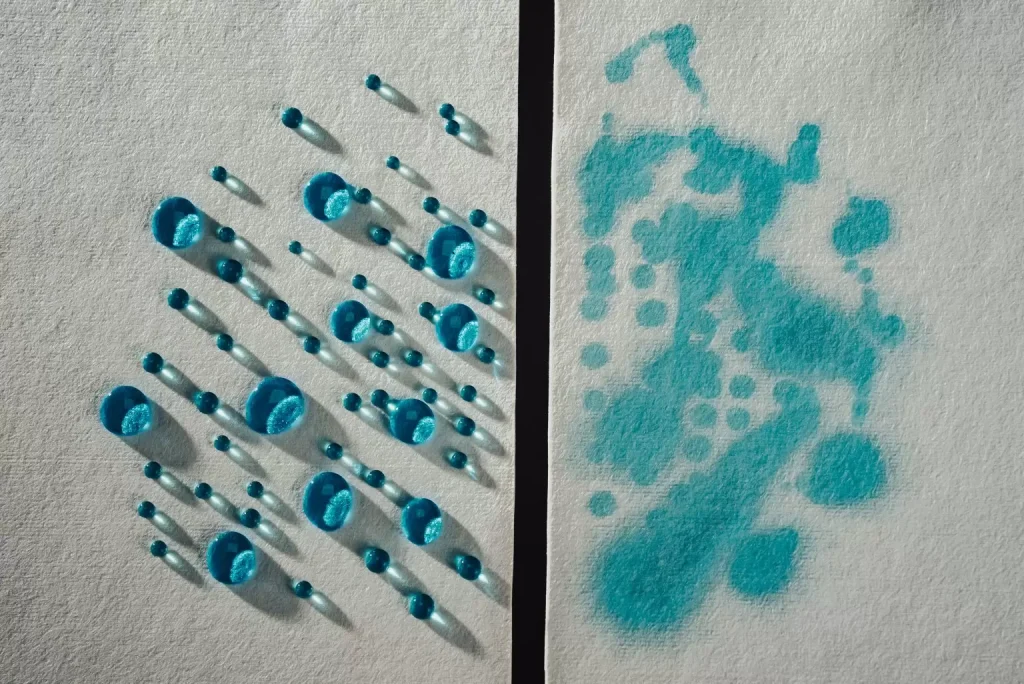

The easy-clean effect, driven by the hydrophobic, oleophobic, and antistatic properties of nanocoatings, plays a significant role in reducing the ecological footprint. These properties create a surface that repels water, oils, and dust, causing contaminants to bead up and slide off with minimal effort. This effect drastically reduces the need for harsh cleaning chemicals, as surfaces can often be cleaned with just water or mild detergents. Additionally, because contaminants do not adhere strongly to the surface, the frequency and intensity of cleaning required are reduced, leading to lower water consumption and less reliance on environmentally harmful cleaning agents. By minimizing the production, usage, and disposal of these chemicals, and by conserving water, nanocoatings contribute to a significant reduction in the overall environmental impact, helping to create a more sustainable approach to surface maintenance.

By giving an example; using nanocoatings on solar panels helps to reduce dust and dirt accumulation, minimizing the need for harsh chemical cleaners, water, and frequent maintenance. This not only conserves resources but also maintains the panels’ maximum energy production efficiency. When dust and dirt accumulate on solar panels, they block or reflect UV light, leading to reduced electricity generation. Nanocoatings prevent this buildup, ensuring optimal performance and reducing the environmental impact of maintenance.

Antimold and anti-graffiti coatings play a significant role in reducing the ecological footprint within industries by decreasing the need for harsh chemicals and frequent maintenance. Antimold coatings prevent the growth of mold and mildew on surfaces, thereby reducing the reliance on chemical treatments that are often harmful to the environment. By protecting the integrity of building materials, these coatings also extend the lifespan of structures, which in turn reduces the environmental impact associated with producing and replacing materials.

Anti-graffiti coatings further contribute to sustainability by creating a barrier that allows graffiti to be easily removed with non-toxic cleaners, reducing the need for harsh solvents and frequent repainting . This not only conserves resources but also lowers the carbon footprint associated with the production and transport of new materials and chemicals. Together, antimold and anti-graffiti coatings enhance the durability of surfaces while promoting a more sustainable approach to maintenance and resource management.

Applying nano ceramic coatings to vehicle surfaces makes cleaning easier, requiring less water and milder detergents due to the easy-clean effect. This is especially important as clean water resources are becoming increasingly scarce, and the use of harsh chemicals contaminates these resources. By reducing water usage and the need for toxic cleaners, nanocoatings help lower the ecological footprint, contributing to more sustainable water management.

Using UV protectant and scratch-resistant nanocoatings on surfaces preserves the original look and properties of objects, extending their lifespan and reducing waste. This also leads to less energy consumption for recycling, which is crucial since a significant portion of energy still comes from fossil fuels. By lowering energy usage and waste, these coatings help to reduce our ecological footprint.

Here is just another example of advanced-level engineered Nasiol nano-coatings being used in different industries helps to extend the lifespan of materials and goods. For example, hydrophobic, oleophobic, and antimold coatings applied to air filters in HVAC systems and the automobile industry prevent mold and bacteria creation on filter surfaces and dust and oil particles from sticking to the filter media 2. This makes filters easier to clean, with the backwash filter cleaning extending their lifespan and reducing waste and energy consumption. Nasiol nano-coatings are already employed by filter manufacturers in industries such as concrete batching plants, cement factories, water purification systems, and automobile cabin pollen filter manufacturers, contributing to more sustainable operations.

Let’s explore some more, how Nasiol products are implemented to reduce the ecological footprint and contribute to a greener future.

Clean energy production:

Nanocoatings play a crucial role in promoting clean energy production by enhancing the efficiency and durability of key energy-generating components. When applied to wind turbine blades, these coatings reduce friction and wear and provide an anti-icing effect, leading to improved performance and longer lifespan. On solar panels, nanocoatings minimize dust and dirt accumulation, ensuring maximum sunlight absorption and optimal energy output. Additionally, when used on geothermal energy pipes, these coatings protect against corrosion and scaling. By improving the performance and longevity of these components, nanocoatings help to maximize clean energy generation, contributing to a more sustainable energy future.

Efficient Coverage:

Nano-sized coatings efficiently cover large areas with minimal product use, with 1 liter covering up to 2,700 square feet (250 square meters), reducing material consumption. Their easy and effortless application helps lower pollution and increase overall efficiency. In other words, only 8-10 grams of product are needed to coat 10.8 square feet (1 square meter) of surface.

Room Temperature and Fast Curing:

Nasiol nano coatings cure at room temperature and fast, eliminating the need for extra energy consumption and additional equipment typically required for heat application. This not only saves energy and initial investment costs but also reduces the ecological footprint.

Lower Temperature Washing:

As nano coating is easy to clean and removes stains which decrease energy consumption, this property reduces the ecological footprint. Lower energy consumption leads to a lower ecological footprint.

Financial Gains of Using Nasiol Nanocoatings

Most new regulations and stricter standards aimed at reducing the ecological footprint often come with added costs. However, as highlighted in this article, nanocoatings not only help protect the environment and living habitats but also reduce long-term costs and increase efficiency. Thanks to their numerous benefits, nanocoatings offer a unique solution that balances environmental responsibility with economical savings.

Final Thoughts

Nanocoatings offer significant benefits by reducing costs and preserving the environment. These advanced coatings make materials more durable and enhance their performance. After applying nanocoatings, you can enjoy financial advantages such as improved product reliability, efficiency, and energy savings, all of which contribute to better overall product performance.

As the world shifts toward sustainable solutions, low VOC (Volatile Organic Compound) products are becoming essential in reducing emissions and protecting the environment 3. Nasiol’s advanced nanotechnology ensures surfaces remain pristine, effectively repelling water, oil, dirt, and UV radiation. Each coating is specially formulated for specific materials, surfaces, and application methods, all developed and manufactured in-house at Nasiol facilities using responsible engineering and production practices.

Nasiol Nano Coatings offers innovative products that are not only technologically advanced but also dedicated to safeguarding our planet and health. Embrace the future of surface protection with Nasiol—where innovation meets perfection.

Summary

Nanocoatings are ultra-thin, durable layers applied to surfaces to enhance protection and reduce environmental impact. Made from advanced materials like silica and titanium dioxide, they offer benefits such as water and oil repellence, anti-corrosion, and scratch resistance. These properties extend the lifespan of products, reduce the need for harsh chemicals, and lower water consumption, contributing to a smaller ecological footprint. Additionally, nanocoatings improve the efficiency of clean energy technologies like solar panels by preventing dust accumulation, thereby supporting sustainable practices. Overall, nanocoatings provide both environmental and financial advantages, making them a valuable tool in modern industry. As Nasiol, which is the leader global manufacturer of surface nano coatings, the company is offering innovative products that are not only technologically advanced but also dedicated to protecting our planet and health.

References:

- https://www.nasiolindustrial.com/the-future-of-graffiti-management-nasiol-anti-grm/

- https://doi.org/10.1016/j.apsusc.2020.145283

- https://www.epa.gov/indoor-air-quality-iaq/volatile-organic-compounds-impact-indoor-air-quality

FAQ

1: How do Nasiol nano coatings reduce ecological footprint?

Nasiol nano coatings require less material to achieve the same or better protective properties compared to traditional coatings. This efficiency means less raw material extraction, manufacturing energy, and transportation emissions, thus reducing overall environmental impact.

2: How do nano coatings extend the lifespan of treated surfaces?

Nano coatings protect surfaces from environmental damage such as mold, cracking, erosion, staining, discoloration, oxidation, UV exposure, abrasion, chemicals, and water ingress, which can damage materials over time. By preventing these issues, nano coatings help to extend the lifespan of treated surfaces, reducing the need for frequent replacements and conserving resources.

3: Do nano coatings reduce maintenance requirements?

Yes, nano coatings can reduce maintenance needs by keeping surfaces cleaner for longer periods. They repel dirt, water, and other contaminants, making surfaces easier to clean and requiring less frequent maintenance with harsh chemicals. The exterior surfaces even clean themselves with rain. For example; solar panels can clean themselves with just rain after they are coated with Nasiol Nano Coatings.

4: How can consumers contribute to reducing ecological footprint with nano coatings?

Consumers can choose nano coatings that are certified environmentally friendly and energy-efficient. By opting for products with minimal environmental impact, consumers can contribute to sustainability efforts and reduce their ecological footprint.

5: Are nano coatings environmentally friendly?

Many of conventional coatings are not formulated to be environmentally friendly, with low or no volatile organic compounds (VOCs) and non-toxic ingredients. However, Nasiol Nano Coatings are all certified and tested and manufactured according to standards. Nasiol Nano Coatings are REACH certified, environmentally friendly and good for human health.

6: Do nano coatings save water and energy?

Yes, nano coatings often require less water and energy compared to traditional methods. They can be applied at room temperature without the need for extensive heating or curing processes, saving energy costs and reducing carbon emissions.

7: What are the benefits of nano coating?

Nano coatings protect the surface of the objects and save them from damage such as scratches, corrosion and other environmental impacts that extend the life of the objects along with durability.

8: What can nanotechnology do for the environment?

Nanotechnology does a great favor in improving environmental sustainability. It reduces waste, improves resource use efficiency, and encourages cleaner production processes. Nanocoatings also do a great job of promoting energy efficiency and reducing pollution.

9: What are nanotechnology products for environmental protection?

Here are the nano-coating products that protect the environment with their advanced technology and properties. The list includes advanced filtration systems, nanocatalysts, and nanocoatings. These products reduce pollutants and strengthen material durability. With energy-efficient applications, nanocoatings are sustainable. Nasiol T series is used in filters, extending their lifespan by keeping them cleaner for longer periods.

10: Who is Nasiol, and what are they doing?

Nasiol Brand and its products, mainly nano coatings developed and manufactured under Artekya Technology Ltd., are their superior performance and durability. Whether it’s protecting automotive surfaces, textiles, glass, or electronics, Nasiol coatings offer unmatched longevity and resistance to wear and tear. The advanced nanotechnology used by Nasiol ensures that surfaces remain pristine, repelling water, oil, dirt, and UV radiation effectively. Specially formulated coatings for every single material, surface, and application area or method are also created under the roof of Nasiol facilities.